Press Brakes

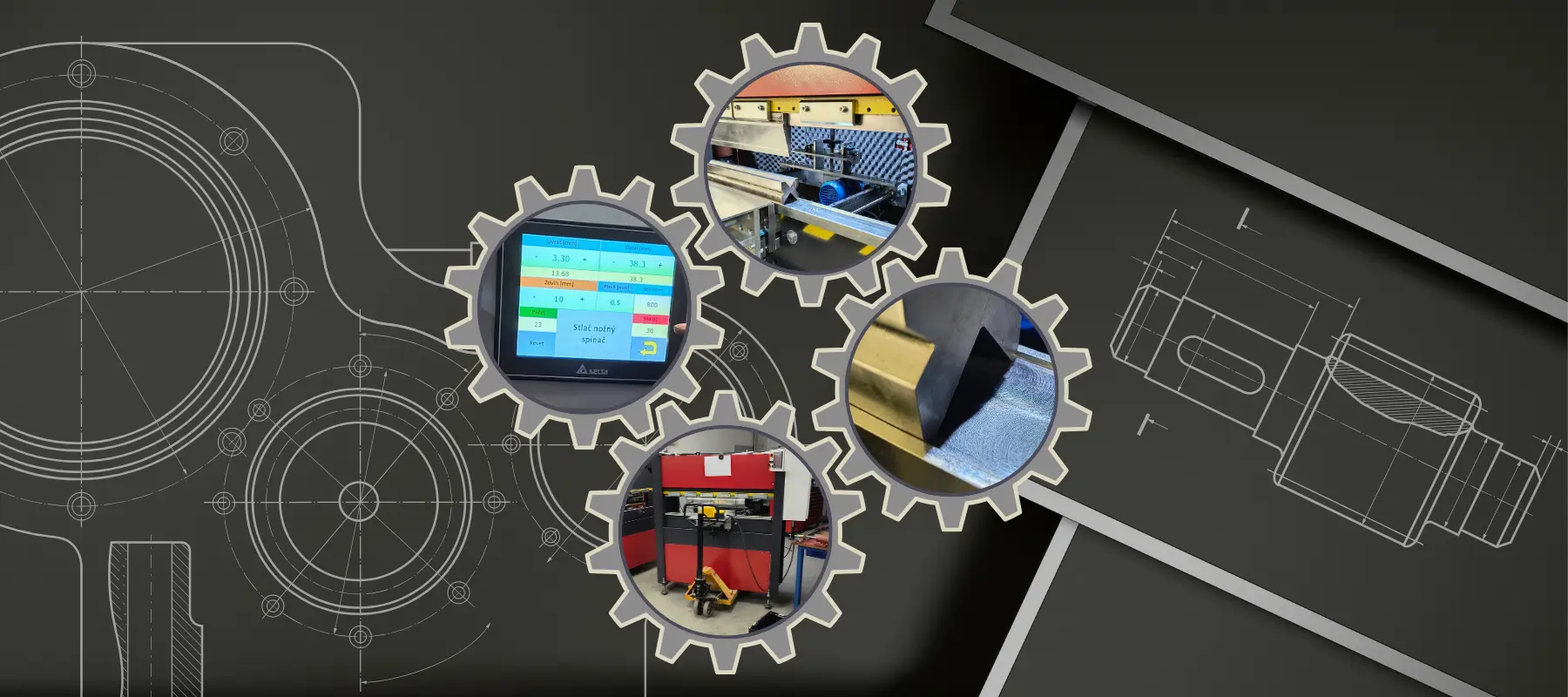

OL-28A Compact Press Brake

The compact press brake is a sheet metal bending machine designed with a focus on space-saving, easy handling, and fast production deployment.

Compared to large CNC presses, it offers:

– smaller dimensions fits into confined spaces

– lower weight, easy to move with a pallet jack

– simpler operation, no special training needed

– lower energy consumption, suitable for smaller workshops

– and a lower acquisition cost, without compromising accuracy.

The OL‑28A model combines the advantages of compact design with performance ready for daily use, it offers a bending force of 280 kN and a working width of 1250 mm.

PLC control with a touchscreen HMI allows for fast setup and intuitive operation, even in environments with rotating operators or without CNC specialists.

The OL‑28A is ideal wherever small sheet metal parts are bent, in small-batch and custom production, service and assembly shops, development and prototyping, or companies that need to bend parts like enclosures, brackets, covers, or supports. Accurately, reliably, and without excessive overhead.

Interested in detailed technical specifications, delivery times, pricing, or an in-person machine demonstration?

Feel free to contact us, we’ll be glad to discuss your specific application.

Contact us| Max. bending force | 280 kN |

|---|---|

| Max. sheet width | 1250 mm |

| Max. operating pressure | 16 MPa |

| Voltage | 3 x 400 V 50 Hz |

| Current | 9 A |

| Motor | 4 kW, 400 V, 1400 rpm |

| Hydraulic oil | HM46 / 32 l |

| Dimensions (H-W-D) | 1750 x 1660 x 600 mm |

| Weight | 1160 kg |

| Blade movement speed | 10 mm/s |

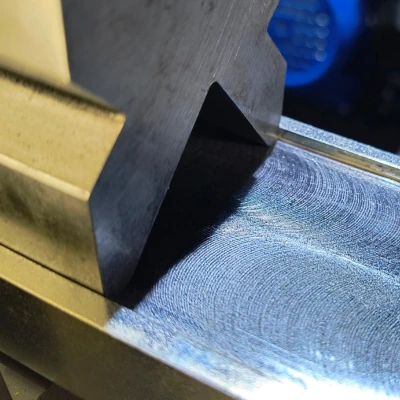

Intuitive Control

The machine is operated via a clear touchscreen interface with a logically structured menu. All main functions are quickly accessible and require no special training to set up.

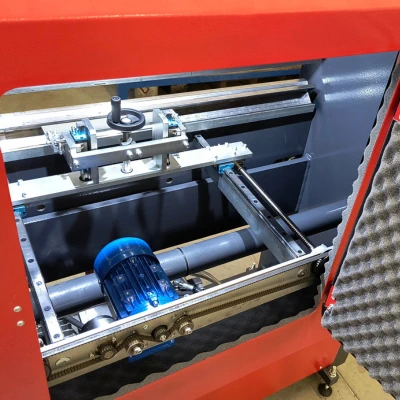

Backgauge

The OL-28A is equipped with a single-axis (1D) automatic backgauge that ensures precise and repeatable material positioning for every bend.

The gauge is electronically driven along the depth axis (X), and the height can be manually adjusted according to the tool or part shape. The system supports bending programs with up to four steps, each with individual settings.

Easy Bottom Tool Clamping

The machine features a universal lower rail with quick-clamping, allowing for convenient and time-efficient tool changes.

Why the OL‑28A?

The OL‑28A is a reliable and economically advantageous solution for companies seeking an efficient press brake without overengineered technology.

Thanks to its simple controls, low maintenance requirements, and fast reconfiguration, it is ideal where production volume or batch size does not justify more expensive CNC solutions.

Interested in detailed technical information, lead times, pricing, or a live machine demo?

Don’t hesitate to contact us – we’re happy to discuss your specific application.

Contact Us